Aqueous Cleaning: Industrial Parts Washer Solutions

Today’s manufacturing demands higher standards. CDF Industries industrial water based parts washers step up to the parts washing challenge with innovative, space-saving and cost-effective solutions for industrial applications requiring consistent part cleanliness quality and machine reliability.

CDF systems perform at a level that will meet or exceed the cleanliness standards for today’s manufacturers. Our systems process parts of all sizes with the same precise and predictable thoroughness. We have experience in manufacturing custom parts washers that remove chips, coolants, oils, deburring grit, dust, stamping compounds and lubricants from parts.

Conveyor Belt Washers

From one stage parts washer to large multi-stage washers, CDF Industries maximizes available floor space with water based industrial conveyor belt parts cleaning systems. Each machine is designed with the parts in mind so that every part is thoroughly and consistently clean. Fully automated, monorail, ult

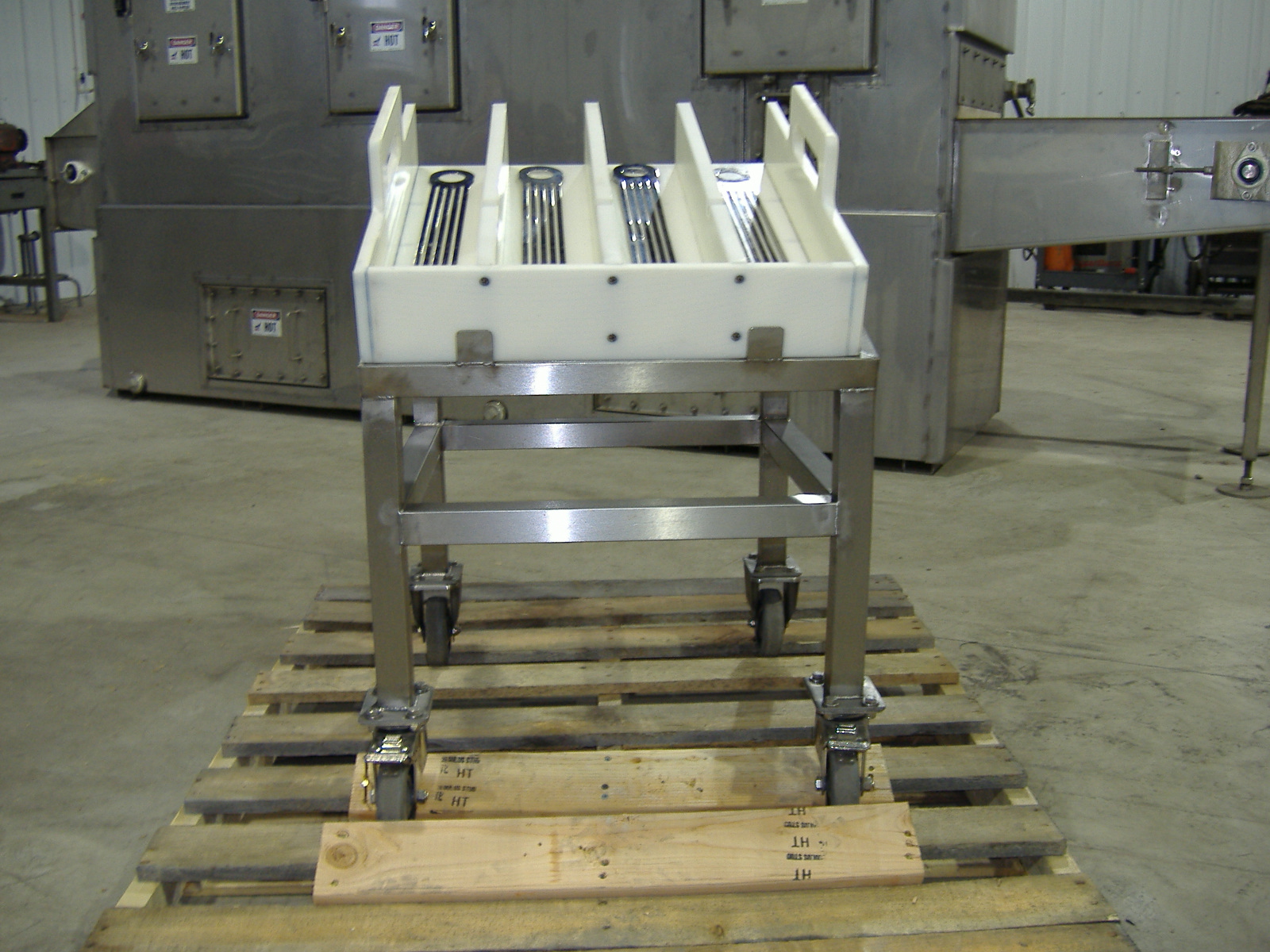

To the left is an example of a custom parts washer designed for an aerospace company. The washer features our pattented gasketless access doors and marine cleanout doors. This washer also utilized brushes on the infeed to maximize the removal of sticky wax on the parts. CDF Industries custom fabricated a cart that “caught” the parts as they came out of the washer.

Rotary Drum

CDF Industries industrial rotary drum washers vary in drum size diameter based on the size of the parts to be cleaned and the quantity to be cleaned in a given shift. Rotary drum washers are designed for high volume parts cleaning with the convenience of inline processing.

The washer to the left was designed to wash small titanium parts in massive quantities. The washer included 2 wash stages, 1 rinse and 1 dry section. The parts washer removed oils, greases, and coolants and left the parts clean and dry upon exit. CDF’s washer was built in conjunction with feed and exit conveyors for a fully automated cleaning process.

Cabinet Spray

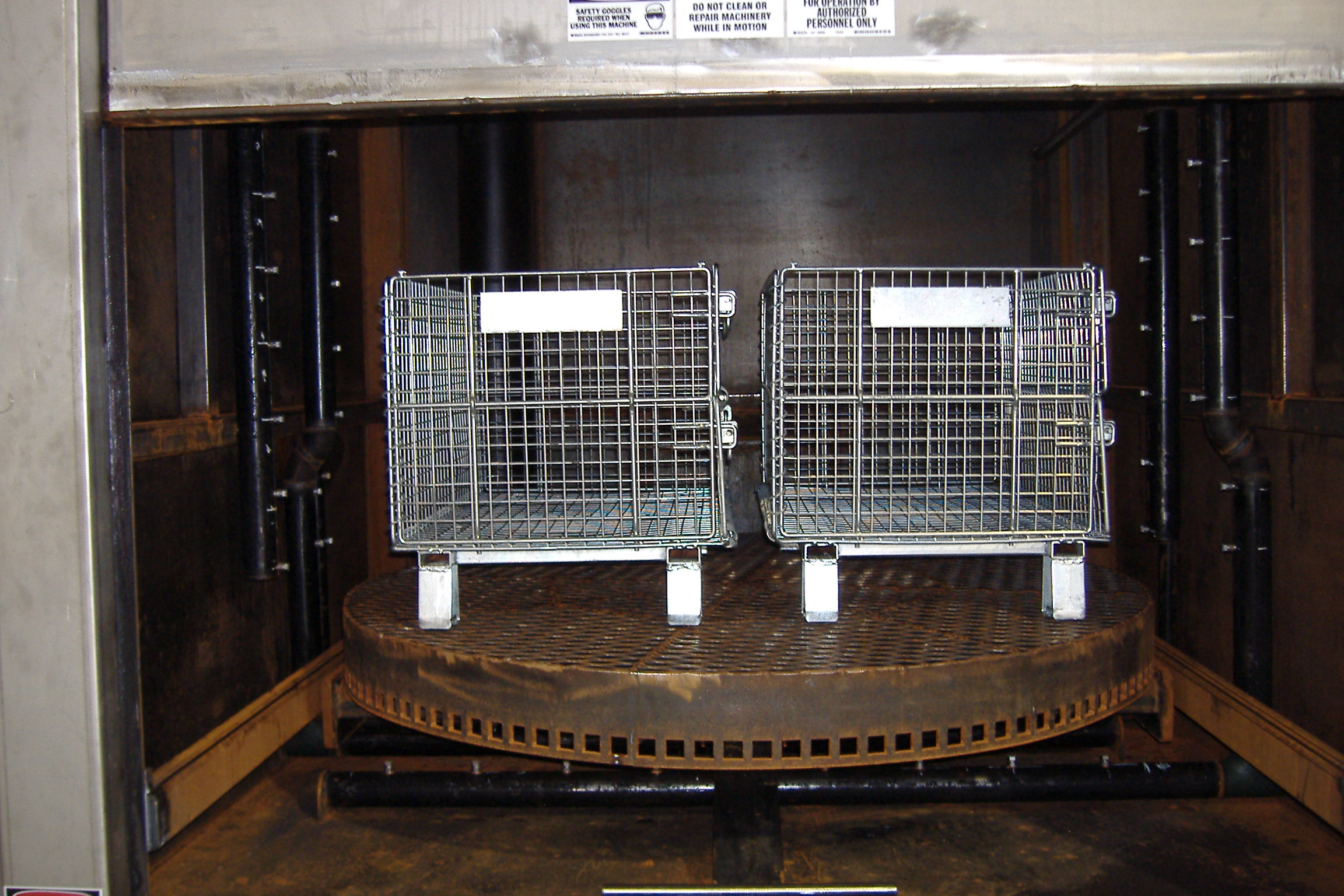

CDF Industries industrial cabinet spray washers come in top loading and front loading designs. These units can be built compactly for smaller parts or with very large diameter turntables and heavy load capacities. CDF’s cabinet spray washers often will have more than one solution tank for wash and rinse stages. Dry cycles can be added as well.

The top loading cabinet washer to the left was designed for a company that manufacturers classified components for U.S. Military use. Given the top secret nature of the parts, CDF Industries was only furnished with materials, approximate sizes and shapes. Even though the parts were never seen, CDF Industries was able to design a top loading cabinet washer that fit seamlessly into an automatic operation and delivered consistently clean parts.

Immersion / Spray Immersion

CDF Industries immersion (dip tank) and spray immersion washers

Bath solutions are usually filtered for particulates and grease/oil.

Vertical Door Washers

CDF Industries vertical door style parts washers are versatile in function and are customized for the parts washed inside. Generally, vertical door washers are used for washing large parts. Spray bars with high pressure nozzles can be aimed to ensure 360 degree coverage. Or, as seen in one of the pictures to the left, hoses have been used to flush “ports” on parts. The table or interior basket smoothly rolls out for part loading and unloading.

Vertical door parts washers often wash, rinse, and sometimes include a dry cycle. Fresh water rinse or a rinse solution tank are optional.

The washers featured to the left feature a bag filter system that filters wash and rinse solutions to dramatically extend bath life.

Ultrasonic Parts Washers

Ultrasonic cleaning is a safe, highly effective way to degrease and remove difficult contaminants from parts. Ultrasonic technology allows for high energy, effervescent bubbles to strip contaminants from the surface of materials aggressively without damaging the part or using harsh solvents.

Ultrasonic cleaning is a safe, highly effective way to degrease and remove difficult contaminants from parts. Ultrasonic technology allows for high energy, effervescent bubbles to strip contaminants from the surface of materials aggressively without damaging the part or using harsh solvents.

The washer to the left is an aqueous cell washer that utilizes ultrasonics during the wash stage. The washer was designed to work on ultra-thin laminations.

Dryers

Air in the dryers can be heated or not, using regenerative or centrifugal blowers and often air knives.